3M™ Xtract™ Low Profile Finishing Back-up Pad (⌀150mm)

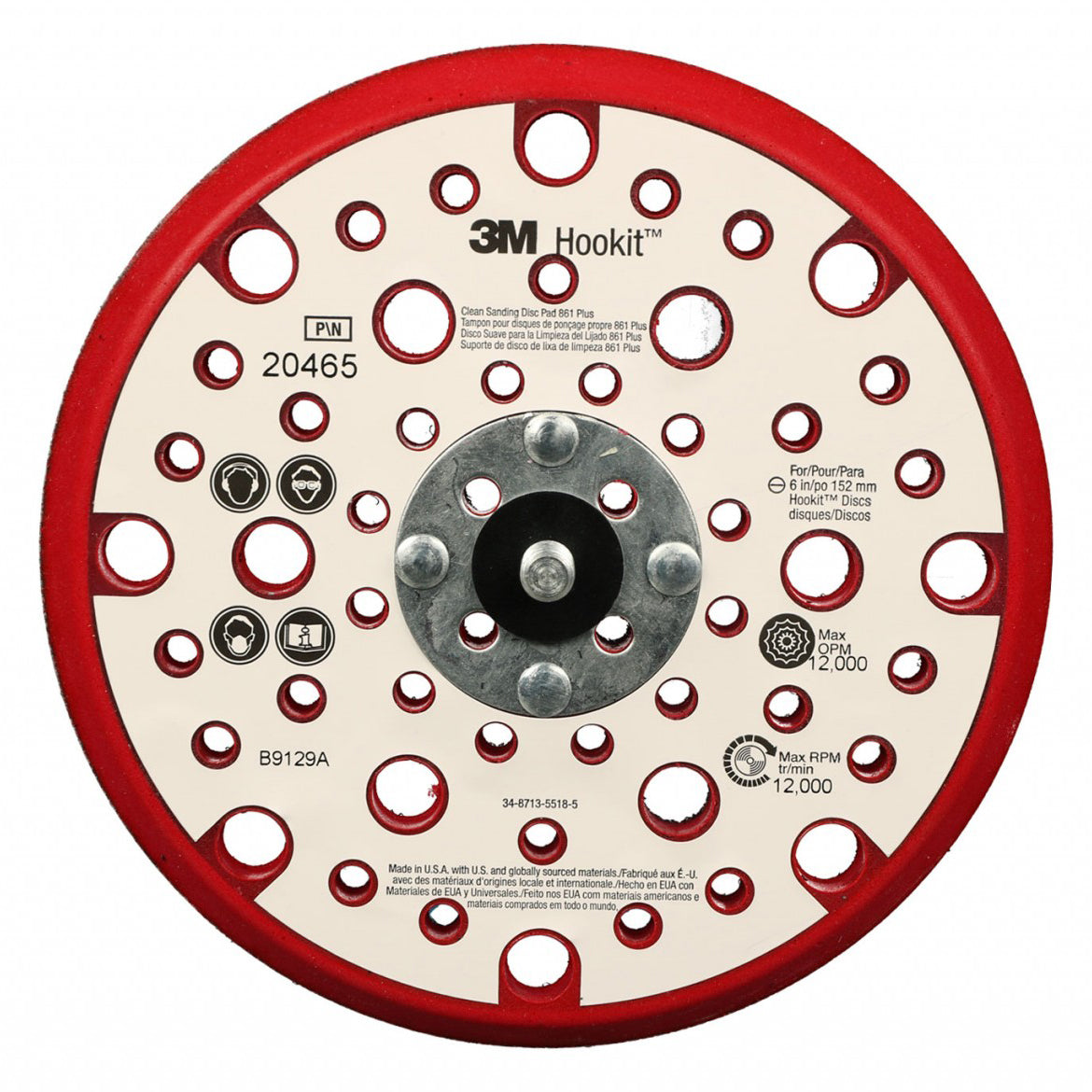

3M™ Hookit™ Clean Sanding Low Profile Disc Pads are strong yet flexible, made from firm density foam with a 35° blunt tapered edge. They’re designed for aggressive flat sanding applications. Use our disc pads to securely hold a 3M™ Hookit™ Clean Sanding Disc* onto a random orbital sander. *Sold separately

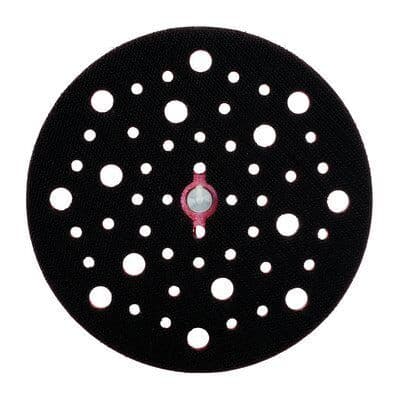

The soft density foam on the 3M Xtract™ Low Profile Finishing Back-up Pad provides additional conformability for final finishing applications where the workpiece has previously been leveled and refined using coarser grade abrasives on firm or medium back up pads. When used with a vacuum and a 3M Xtract abrasive disc, the series of uniquely designed holes and channels allows dust to be pulled through the holes and away from the sanding surface to prevent loading, increase productivity, and provide a cleaner work environment. The disc pad has external threads compatible with an orbital or random orbital sander. Our proprietary multi-hole pattern works with a vacuum to help eliminate dust from the disc, workpiece and air. Sandpaper discs cut better and last longer when dust isn’t loading the cutting surface of the abrasives. Reducing dust is easier than ever with 3M Xtract Discs, designed for optimal dust removal. For maximum dust extraction, use this disc with a 3M Xtract Back-up pad and a random orbital sander with vacuum (both sold separately). Our proprietary multi-hole pattern on 3M Xtract products removes dust at a higher rate than 5- or 6-hole products. This hole design doesn't even require alignment of holes with the back-up pad (which is attached to a random orbital sander and sold separately), making disc changes quick and simple. The 3M™ Hookit™ attachment system uses a hook and loop design that makes disc changes fast and easy. All of this adds up to improved productivity and reduced material consumption. Reducing dust dramatically increases the cutting efficiency and life of the disc, which ultimately reduces operating costs.