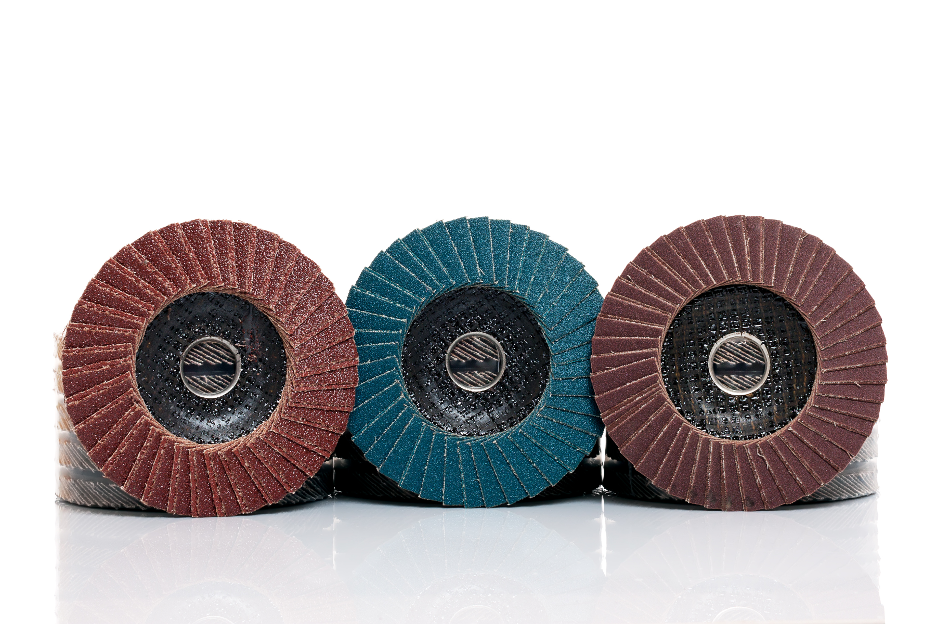

Sanding is essential in many projects, whether you are working with metal, wood, stone, or other materials. However, successful sanding depends on the correct choice of tools and technique. Sanding discs are versatile, each designed for specific uses. This article examines three main types of discs – for metal, wood, and concrete – and provides practical tips for their use, emphasizing proper angles, pressure, and safety. Understanding these techniques will not only improve the final result but also allow for more efficient work with less effort.

Metal Sanding Discs

Discs designed for metal are ideal for removing rust, smoothing weld seams, and cleaning old paint. The abrasive material in these discs, such as aluminum oxide, ensures effective sanding even on hard surfaces. When working with a metal disc, it is recommended to hold the sander at an angle of approximately 15–30 degrees to the surface to avoid gouging. It is important not to overdo the pressure, as it can cause overheating, negatively affecting both the quality of work and the tool's lifespan.

Wood Sanding Discs

Wood surfaces require a particularly gentle approach, often using sandpaper discs. These sanding discs are suitable for both smoothing raw wood and removing lacquer or paint. To ensure the wood grain is not damaged, it is recommended to choose a disc with lower abrasiveness, such as P80–P120. When working, movements should follow the grain, and pressure should be light and even to avoid indentations or oversanding. Be sure to consider the type of wood being worked on, as softer woods require less abrasiveness than harder ones.

Stone and Concrete Sanding Discs

For hard materials like stone or concrete, specialized discs are the best choice. These offer high wear resistance and are ideal for smoothing concrete surfaces or rounding stone edges. When working with these abrasive discs, the sander should be held steady, and pressure should be moderate to avoid cracks or surface damage. Adding additional cooling with water helps reduce overheating, which is especially important for extended tasks. To achieve precise results, ensure the disc is suitable for the specific material and task before starting work.

The choice and proper use of sanding discs are key to achieving the best results in various projects. Each material—metal, wood, or concrete—requires a different approach, so it is crucial to follow proper techniques, such as angle and pressure. Combining these skills with safety measures allows beginners to confidently start their tasks and avoid mistakes that could damage the surface or create risks. Additionally, understanding the properties of different discs and techniques can significantly enhance productivity and accuracy in results.