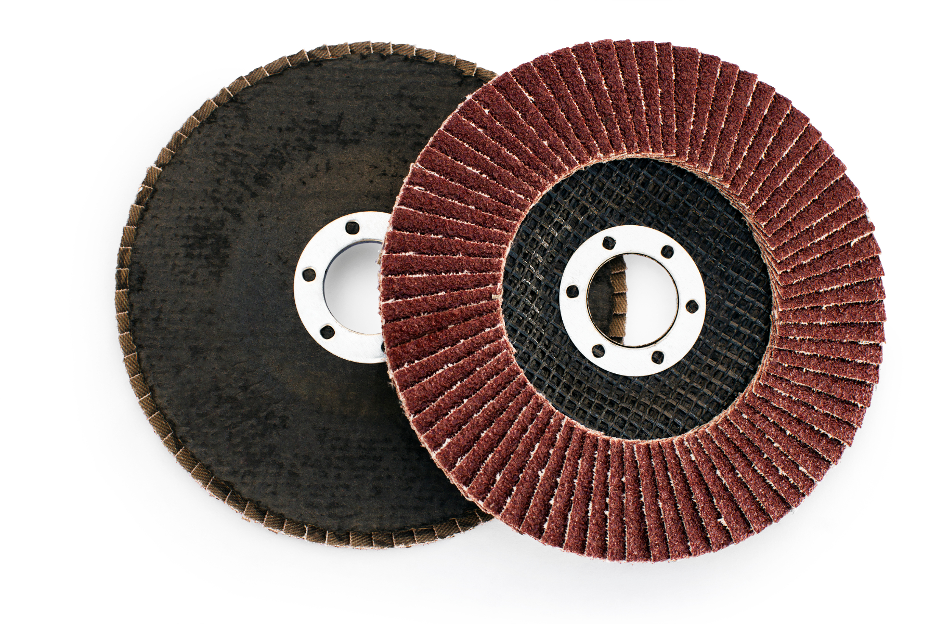

Grinding discs are an essential tool for various tasks, ranging from metalworking to construction. However, frequent replacements can become a significant financial expense if the discs are not used and maintained properly. In this article, we will explore methods to help maintain the efficiency and durability of grinding discs by focusing on proper usage, maintenance, and storage.

Proper Usage – The Key to Efficiency

The correct use of a grinding disc is one of the main factors in extending its lifespan. It is important to follow the operating parameters set by the disc manufacturer, such as speed limits and the recommended type of material. Working with excessive pressure or at an improper angle can lead to uneven wear or even damage to the disc. Additionally, the work surface should be clean and free from debris that could cause unnecessary friction. During use, overheating should be avoided, as it can damage the disc structure and reduce its efficiency. Furthermore, it is advisable to regularly check whether the equipment is properly calibrated, as incorrect machine adjustments can accelerate disc wear.

Regular Maintenance and Disc Care

The lifespan of a grinding disc is also significantly influenced by regular maintenance. After each use, the disc should be cleaned of accumulated dust, metal, or other residues. Dirt can reduce the disc’s cutting ability and place additional strain on the grinding machine. It is also recommended to inspect the disc before each use for cracks or other damage. Even minor damage can cause the disc to break during operation, which is not only costly but also dangerous. Specialized tools or substances designed for abrasive material maintenance can be used for cleaning the disc.

Proper Storage – A Long-Term Investment

To maintain the efficiency of grinding discs, proper storage is also crucial. Discs should not be exposed to moisture, which can cause corrosion, or direct sunlight, which can damage the material’s structure. The best storage location is a dry, cool room with a stable temperature. It is recommended to store the discs in a horizontal position to prevent deformations. Additionally, care should be taken to ensure that the discs are not compressed or subjected to excessive weight. Special storage racks or boxes can help keep the discs properly organized and easily accessible.

The lifespan of grinding discs directly depends on how carefully they are used, maintained, and stored. By following these simple principles, it is possible not only to save money but also to ensure safer and more efficient work. Therefore, let’s take care of our tools—they are the foundation of our work quality and success! With the right approach to grinding discs, you can maximize their potential and minimize unexpected work interruptions.